Versatile, durable and extremely affordable, PVC sheeting is seeing exponential growth in dozens of applications and industries, ranging from home renovations and DIY projects, to furniture, retail signage, greenhouses and more.

With a long list of favourable properties, including water, chemical and impact resistance, PVC sheets and panels are steadily replacing traditional options like tiles and plasterboard in interior residential and commercial uses, and brick, wood and metals in more demanding exterior applications.

PVC Panel Basics

Polyvinyl chloride, a tough and lightweight thermoplastic renowned for its mechanical, chemical and weathering resistance, is the core ingredient in PVC panels. The material is easily formed and machined into a variety of profiles and shapes, with panels primarily produced via extrusion. Raw PVC resin is blended with additives, including heat and UV stabilisers, plasticisers, fillers and colourants. The mixture is fed through an extruder (conical, twin-screw extruders for better mixing and consistency, or single-screw extruders for affordable, high-volume production), which applies pressure and heat to produce a molten mixture.

This is fed through a die to create a continuous profile, and then passes through water-cooled rollers or vacuum chambers, where it solidifies and assumes its final thickness and dimensions. Additional processes, such as embossing and laminating, alter PVC panel surface finishes and textures, providing versatility and aesthetics. Panels are then cut to the desired lengths and widths, undergo quality inspection and are packaged.

Properties and Benefits

Extruded PVC panels offer a wide range of benefits, especially as an affordable alternative to traditional materials such as wood, tiles, metals and concrete. Standout advantages include:

- High durability: Resistant to moisture, mould, chemicals and impact, PVC sheets and panels are ideal choices for kitchens, bathrooms, and basements, ensuring consistent long-term performance. Panels won’t corrode or rust, unlike many metals, or rot like wood, and offer comparable durability, finishes and textures to tiles, without the high purchase and installation cost.

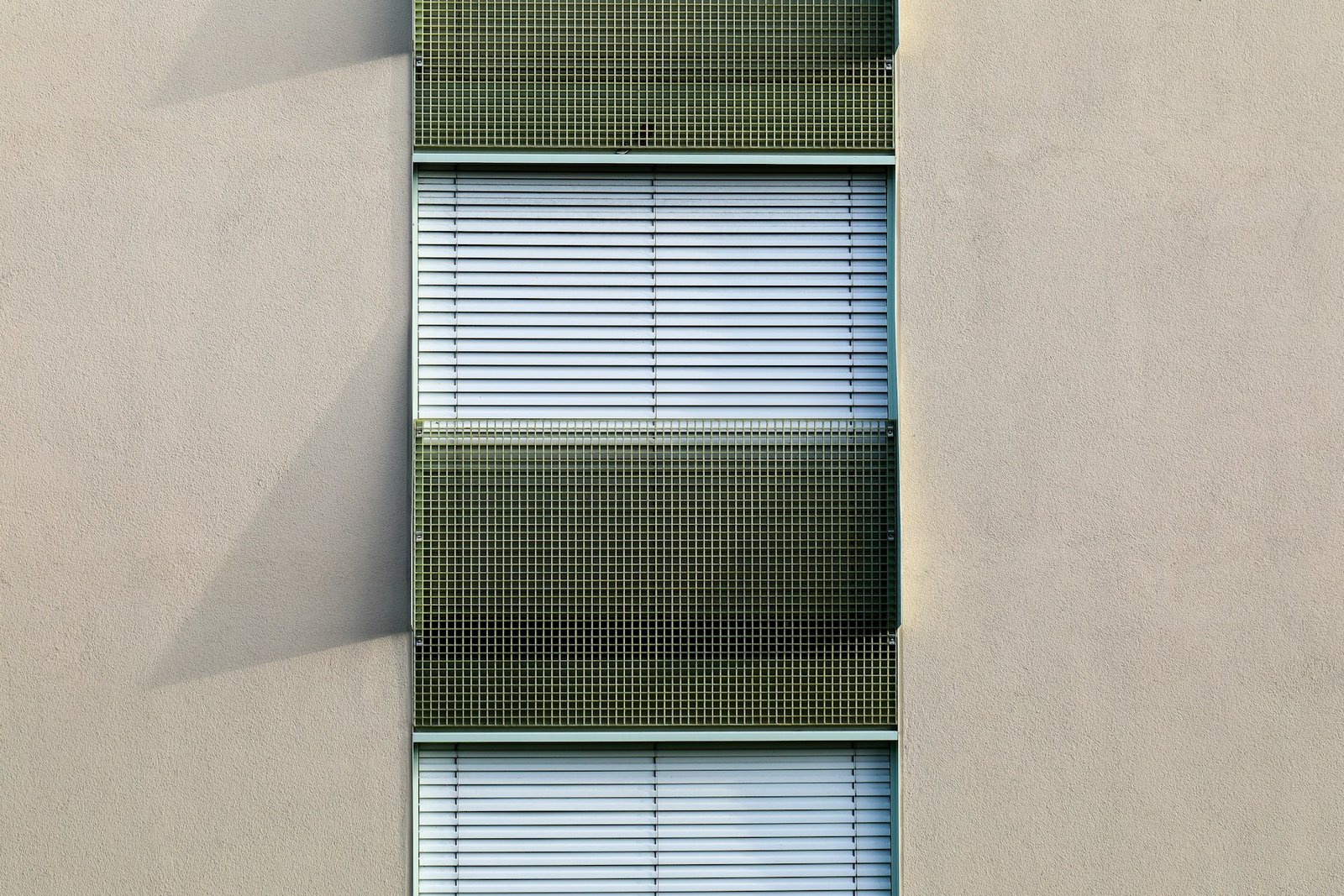

- Suitability for exterior applications: On a similar note, water and UV resistance, and protection against pests like termites, make PVC sheeting a cost-effective option for exterior uses such as cladding and porch ceilings. This versatility further improves with low thermal conductivity, ensuring good insulation. Moreover, the use of fire retardants and high chlorine content provides compliance with building codes, as panels self-extinguish and prevent flame spread.

- Low maintenance and easy cleaning: The smooth, non-porous surface requires minimal upkeep. While wood often requires the use of paint and sealant, and metals are heat-treated and coated to prevent rust and fading, PVC retains its clean look with occasional cleaning, needing only a simple swipe with mild detergent and water.

- Cost-effectiveness: Low purchase prices, simple installation and proven longevity make PVC sheeting a cost-effective option across multiple uses.

- Low weight: Panels are significantly lighter than the materials they replace, with common 2mm and 2.5mm thick sheeting in standard building sizes of 2400mm by 1200mm weighing between 8 and 12 kilos per panel. This makes for easy transport and simple handling, cutting labour costs.

- Versatility: Extrusion ensures a variety of shapes, sizes and textures and pigments and colourants provide variety in colours. With numerous finishing processes, from lamination and printing to painting and powder coating, panels additionally offer the versatility and aesthetic appeal for dozens of interior and exterior applications.

Common PVC Panel Types

By Construction

Hollow or honeycomb panels feature internal ribs that blend aesthetic appeal and low weight for decorative uses, such as false ceilings, partitions and bathroom panelling. With good impact absorption and insulative properties, they’re also seen in exterior uses, including wall cladding and roofing, though surpassed by uPVC types for outright durability. Similar uses are shared by foam-backed and foam-core panels, benefitting from simple shaping and machining (cutting, drilling, routing) for more detailed architectural uses, such as interior walls, window and door trims, and soffits.

Solid panels are commonly thicker and denser, and more robust and durable. These are seen in signage, kitchens and cabinetry, custom furniture pieces (including shelves and cabinets), exterior wall cladding and areas where high strength and water resistance are required.

Unplasticised (uPVC) panels trade flexibility for sheer strength. By substituting plasticisers for calcium carbonate, glass fibres and polystyrene or MDF in sandwiched designs, rigid uPVC panels go with increased hardness, higher heat resistance and better dimensional stability in demanding commercial and industrial applications, including roofing sheets, vehicle cladding, medical cabinets, storage tanks and more.

By Finish and Style

To achieve specific styles and finishes, PVC resin is blended with a variety of additives or undergoes finishing processes. UV-cured coatings and high-gloss lamination result in a gloss finish, preferred for bright, reflective surfaces to enhance airiness and make rooms, such as kitchens and bathrooms, seem larger.

Alternatively, matte finishes are achieved by adding matting agents (such as silica, talc, calcium carbonate, or waxes) or by hot-pressed or vacuum-applied lamination. This works best in bedrooms, living rooms, and areas requiring a more understated aesthetic. Ultra-matte panels often include higher matting agent ratios, specific plasticisers or the addition of coatings to produce PVC sheeting in a refined, soft-touch, non-reflective look. These are seen in kitchen backsplashes and countertops, shower enclosures, custom closets and home and office furniture.

Textured panels, designed to mimic the look and feel of stone, marble, brick and wood grain, are popular options in interior wall panelling, adding dimensional depth, detail and tactility. Similarly, embossed panels in 3-dimensional designs draw attention in decorative ceilings, walls and furniture in living rooms, bathrooms, and bedrooms. These are also widespread in hotels, offices and other commercial areas.

And to meet different tastes and design requirements, choose from the wide selection of colours. This includes all shades of whites, grays and blacks, earthy tones in cream, beige or brown for a warm and inviting aesthetic, or bolder and more vibrant options in blue, red, orange, yellow or pink for a cohesive look in commercial premises and workspaces.

Where They’re Used

Key areas where PVC panels make a difference are the construction and renovation sectors, with panels used in wall cladding, interior wall partitions, ceilings, doors and windows, roofing (in uPVC types), siding, soffits and decking. On a similar note, furniture made from lightweight, water and mould-resistant PYC panelling is an affordable alternative to costlier hardwoods and metals, while benefiting from easy fabrication for kitchen cabinets, shelving, wardrobes, tables and more. The materials also feature in advertising and signage, including banners, displays and exhibition stands with laminated types ensuring legibility and high weathering resistance.

Commercial and industrial uses include storage tanks due to the panels’ good heat and chemical resistance, partitions and machinery barriers with high impact resistance, and areas like food processing benefiting from easy cleaning for improved hygiene. Similar uses are in agriculture. Thicker transparent panels are common in greenhouses (with high light transmission) and animal enclosures due to the material’s strength, simple maintenance and affordability.