Laser engraving is a precise and versatile method used for creating detailed designs on various materials such as wood, metal, glass, and acrylic.

Whether you’re crafting intricate artwork, engraving fine text, or producing professional-quality branding, achieving sharp and detailed results is essential.

This guide will explore key tips to help you maximize the detail in your laser engraving projects.

Choosing the Right Laser Engraver

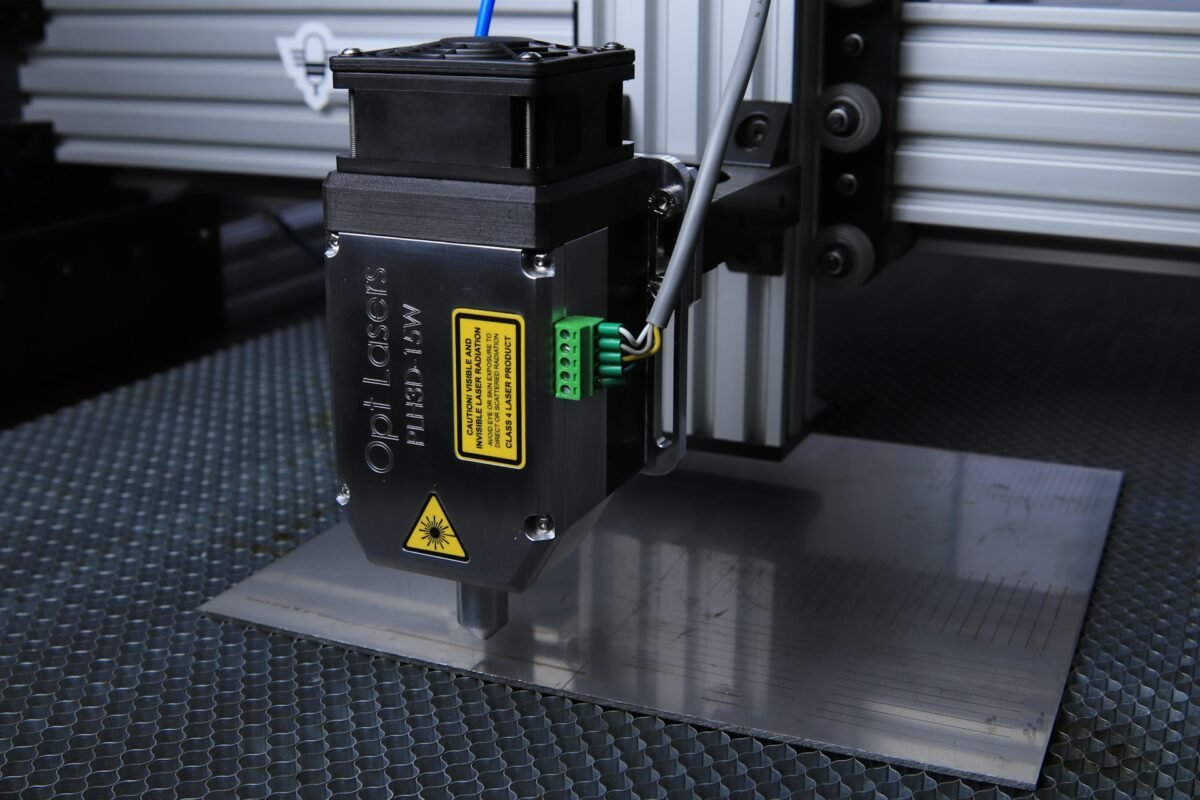

The type of laser engraver you use significantly impacts the level of detail you can achieve. Consider the following options:

- CO₂ Laser: Ideal for engraving organic materials like wood, leather, and acrylic.

- Fiber Laser: Best for engraving fine details on metals and certain plastics.

- Diode Laser: Suitable for lightweight and hobbyist projects, but may lack the precision of CO₂ or fiber lasers.

Key specifications to look for include:

- Resolution (DPI – Dots Per Inch): Higher DPI settings allow for finer engraving details.

- Spot Size: A smaller laser beam spot produces sharper lines and intricate designs.

- Power Settings: Adjustable power ensures better control over depth and precision.

If you are looking for a user-friendly laser engraving machine, a high-quality OMTech laser engraver is what you are looking for. OMTech offers a series of CO₂ laser and fiber laser machines that can fit your needs.\

Material Selection and Preparation

Different materials respond uniquely to laser engraving, so choosing the right one is crucial:

- Best for Fine Detail: Anodized aluminum, acrylic, and coated metals.

- Challenging Materials: Softwoods (grain may interfere with detail), glass (can chip if not handled correctly).

Preparation Tips:

- Clean the surface to remove dust and debris.

- Use masking tape on materials like wood to prevent burn marks.

- Ensure the material is flat and securely positioned to avoid movement.

Optimizing Engraving Settings

Fine-tuning your laser engraving machine’s settings can make a significant difference in the final output:

Power and Speed: Lower power with a slower speed ensures precise engraving without excessive burning or charring.

DPI Settings: A DPI of 300-600 is recommended for crisp details; too high can cause excessive burning.

Multiple Passes: Engraving in multiple light passes rather than one deep pass helps maintain clarity.

Focusing and Lens Considerations

Proper focus is essential for sharp detail. Adjust the focal distance according to your engraver’s specifications.

Use a shorter focal length lens (e.g., 1.5 inches) for finer detail engraving.

Regularly clean the lens to prevent residue buildup that can blur the engraving.

Using High-Quality Artwork and Vector Graphics

Use Vector Graphics: Formats like SVG, AI, or EPS allow for clean, scalable designs compared to pixel-based raster images.

Increase Contrast: Convert grayscale images into high-contrast black and white to improve engraving clarity.

Avoid Low-Resolution Images: Blurry or pixelated images will translate into rough engravings.

Proper Cooling and Ventilation

Use an Air Assist System: This helps prevent material scorching and improves engraving clarity.

Ensure Proper Ventilation: Engraving produces smoke and fumes that can interfere with laser precision. A good exhaust system keeps the workspace clear.

Testing and Calibration

Always conduct test engravings on scrap material before final production.

Use focus calibration tools to ensure the laser beam is properly aligned.

Regularly check and realign the laser bed to maintain accuracy.

Post-Processing for Enhanced Detail

Clean the Engraved Surface: Use isopropyl alcohol and a soft cloth to remove residue.

Polish Metal Engravings: A fine brush or polishing compound can enhance metallic engravings.

Seal Wood Engravings: Applying a clear coat can deepen contrast and protect the design.

Conclusion

Achieving fine detail in laser engraving requires a combination of the right equipment, proper material preparation, precise settings, and post-processing techniques. By following these tips, you can elevate the quality of your laser engravings and produce professional-grade results. Remember, practice and experimentation are key to mastering the art of laser engraving!