The European watch market doesn’t mess around. Consumers here know their stuff. They’ve grown up around mechanical watches. They understand movements.

They can spot quality from across a room. So when a brand gets noticed in this environment, it means something. Tufina Watches has been getting noticed. Not through flashy marketing campaigns or celebrity endorsements. Through the watches themselves. Let’s talk about why.

Tufina Watches Theorema Kingston GM-117-5: Automatic Full Calendar Watch.

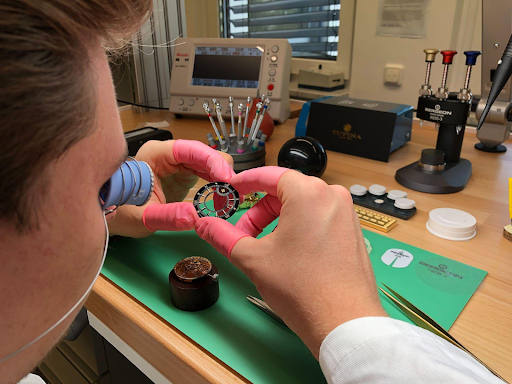

The Hand-Assembly Difference

Most people don’t realize how watches are actually made today. Even expensive ones. Even brands charging five figures. They use automated assembly lines. Machines do most of the work. Humans just supervise.

At Tufina, every single watch is assembled by hand. A watchmaker sits at a bench with tools and components. They build the watch piece by piece.

The case gets examined. The movement gets tested. Each step gets fitted manually.

This takes time. A lot of time.

A simple three-hand watch might take several hours. A complicated piece with a tourbillon? Days. Maybe weeks for the most complex models. But here’s what you get: accountability. When one person assembles your watch, they stake their reputation on it. If something goes wrong, there’s no hiding behind “the production line.” It’s personal.

Technology Meets Tradition

Here’s where it gets interesting. Tufina uses modern technology. They have precision instruments. Computer-aided design. Advanced testing equipment. They’re not working with 19th-century tools. But the assembly? Fully manual.

They use technology for precision. For quality control. For ensuring tolerances are perfect. But human hands put everything together. Think of it like a master chef using a high-end oven. The technology helps. But the skill? That’s human.

Every movement gets monitored manually. Watchmakers check timing. They test accuracy. They adjust until it’s right. No automated pass/fail system. No “good enough” threshold programmed into a computer.

This hybrid approach makes sense. Use technology where it improves quality. Keep humans where judgment matters.

Limited Production Reality

Tufina doesn’t make many watches. They can’t. Not with 100% hand assembly. Not with manual monitoring. Not with their quality standards. The Theorema line produces limited quantities each year. Some models get made in runs of a few hundred. Others? Maybe fifty pieces. Tourbillon models might be even more restricted. Pionier follows the same model. Small batches. Careful production. No rushing.

This isn’t artificial scarcity. It’s a mathematical reality. You can only assemble so many watches by hand in a year. There are only so many skilled watchmakers. Only so many hours in a day. Some brands create fake scarcity for marketing. They could make more but choose not to. Tufina actually can’t scale up without compromising their process. That limitation becomes a feature.

What Hand Assembly Really Means

Let’s get specific about the process. A watchmaker starts with the movement. This is the engine. The heart. Everything depends on it working perfectly. They place the mainplate. Add the bridges. Install the gear train. Each wheel must mesh correctly. Each jewel must seat properly. The balance wheel needs perfect poise. Then comes regulation. Adjusting the beat. Fine-tuning the amplitude. Testing in multiple positions. This alone can take hours. The movement goes into the case. But first, the case gets inspected. Any scratches? Any imperfections? Hand-assembled doesn’t mean sloppy.

Dial installation requires steady hands. One fingerprint ruins it. One spec of dust means starting over. Hands get fitted. They need to clear each other perfectly. They need to align exactly at midnight. Sounds simple. It’s not. Crystal goes on. The case back gets sealed. Then testing begins again. Water resistance gets checked. Timing gets verified. Power reserve gets measured. If anything’s off, back to the bench. This is why hand assembly matters. Machines follow programs. People make decisions.

Noah Tufina hand-assembles watches at Tufina Workshop.

The European Advantage

Europe has a watch culture that’s hard to explain. It’s not about showing off. It’s about appreciation. Europeans understand that a watch is more than a time-telling device. They know movements. They discuss complications at dinner parties. They inherit watches from their grandparents.

German watchmaking has its own character. It’s different from Swiss. Less flashy. More engineering-focused. Precision matters more than prestige. Tufina fits perfectly into this tradition. Munich headquarters. Attention to mechanical excellence. Focus on substance over style.

But they also understand modern consumers, which is why we believe this brand has become even more popular in recent years.

Comparing Value Propositions

Let’s talk about what you actually get. A fashion watch costs maybe $150? You get a quartz movement. Mass production. Brand name on the dial. It tells time. That’s about it. It’ll last a few years. Maybe five if you’re lucky. Then the battery dies, and you buy another one. Or the movement fails, and it’s not worth repairing.

Tufina watches start higher. But you’re getting mechanical movements. Hand assembly. Real complications. Proper materials. The tourbillon models feature one of watchmaking’s most difficult complications. From Swiss brands, tourbillons start at $50,000. Often much more. Tufina offers them at a fraction of that price, starting at about $3000.

How? No massive marketing budgets. No retail markup. No luxury conglomerate taking a cut. Direct sales model. Focused production. That’s the main reason why independent European brands such as Tufina are taking the market by storm.

Durability and Longevity

Mechanical watches last. That’s just physics. No batteries to die. No quartz crystals to fail. No electronic components to corrode. Just gears, springs, and jewels. Maintained properly, a mechanical watch runs for generations. Your grandfather’s watch still works. Your great-grandfather might too.

Tufina builds with this timeline in mind. High-grade stainless steel cases resist corrosion. Sapphire crystals don’t scratch. Mechanical movements can be serviced indefinitely. Compare that to a quartz fashion watch.

The movement fails? You throw it away. The battery dies repeatedly? Eventually, you stop replacing it.

Even expensive quartz watches have limited lifespans. Electronic components age. Parts become unavailable. After ten or fifteen years, you’re done. A mechanical Tufina? Service it every five years. It’ll outlive you.

Why European Brands Matter in 2025

Let’s be honest, the watch industry has a problem. Luxury conglomerates own most brands. They standardize production. They maximize profits. They treat watches like any other luxury good. Independent European brands offer an alternative. They’re not answerable to shareholders. They’re not hitting quarterly targets. They make watches because they care about watches. This shows in the product. Decisions get made for watch reasons, not business reasons. Complications get added because they’re interesting, not because they test well with focus groups.

Tufina fits this description. Their watches are precisely executed. Carefully assembled. Thoroughly tested. And being a niche brand also has its benefits. You’re not wearing what everyone else wears. You’re not seeing your watch on every third wrist. You’re wearing something distinctive.

There’s also the conversation factor. Someone notices your watch. They don’t recognize the brand. That opens dialogue. You explain the history. The process. The complications. Try that with a mainstream brand. “Oh, I know that logo.” Conversation over. Niche brands create community. Owners connect. They share experiences. They appreciate what they have. Tufina owners seem to understand this. They’re not buying for status. They’re buying for substance.

Tufina Watches Theorema Singapore GM-131-7: Automatic Skeleton Watch.

Direct Sales Model Benefits

Tufina sells primarily through its official website and a few official physical stores. This matters more than you’d think. Traditional watch retail involves massive markups. The brand sells to a distributor. The distributor sells to a retailer. The retailer doubles the price. A watch that costs $1,000 to make might retail for $4,000 or more. Most of that isn’t going to craftsmanship. It’s going to the middlemen. Direct sales eliminate this. The savings go to either better components or lower prices. Usually both.

You also get direct communication. Questions go to people who actually know the watches. Not retail staff reading from spec sheets.

Who These Watches Are For

Tufina isn’t for everyone. If you want maximum brand recognition, buy Swiss. If you want ultra-exclusive, spend six figures. If you just need to know the time, buy a quartz. But if you want proper watchmaking at honest prices, Tufina makes sense. If you appreciate mechanical complications without emptying your savings, they’re worth considering. If you value craftsmanship over brand names, look closer.

These are watches for people who understand watches. Or for people learning to understand them. They reward attention. The more you know about watchmaking, the more you appreciate what Tufina does.

The Bottom Line

European watch brands get noticed when they deliver. Tufina delivers. Hand assembly. Manual monitoring. Limited production. Quality materials. Honest pricing. Long watchmaking history. They’re not perfect. No brand is. But they’re doing something meaningful in a market often dominated by marketing over substance. The watches work. They last. They look good. They offer genuine value for the price.

In an industry where fashion watches pretend to be luxury and luxury watches pretend to be fashion, Tufina just makes authentic watches. Good ones. Built to last. That’s why they get noticed. Sometimes the best marketing is just making something good.