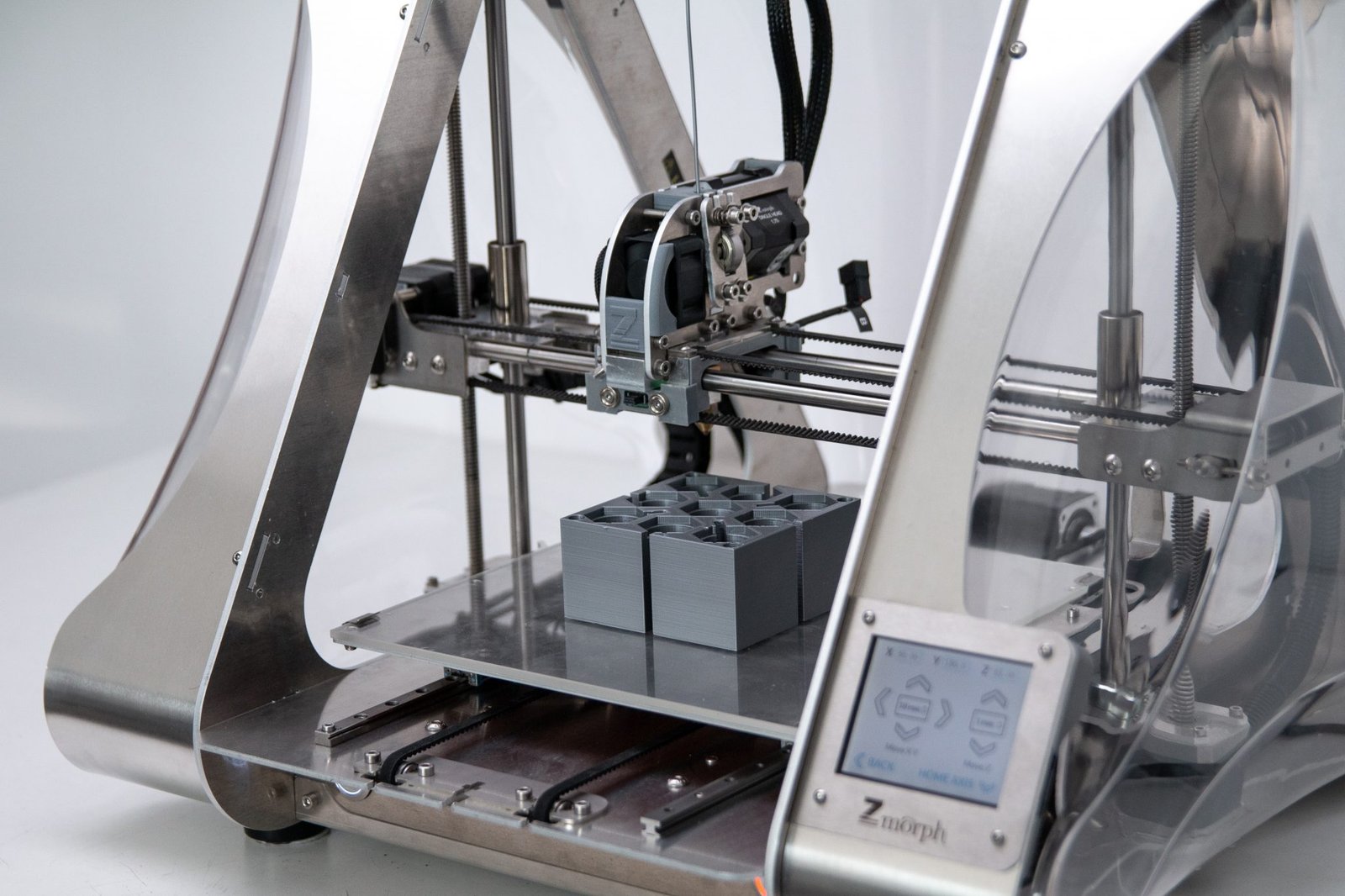

How To 3D Print Metal At Home

3D printing is truly revolutionizing the world we live in.

It has enabled us to make 3D models of anything we can envision and are willing to create.

Pretty soon, there may be as many printers in homes as there are paper printers. Most 3D printers make their models in plastic.

On the other hand, there are new 3D printers that allow you to print metallic objects, which is incredible. You can now do from the comfort of your home what was previously only possible in a large manufacturing plant. However, the price of 3D metal printers is still too expensive for most people, but as more are produced, the price should reduce. There are so many applications for a 3D metal printer, they are literally endless.

The following is how you can use a 3D printer to make metal at home:

Get a Filament

The first item you will need to 3D print metal at home is a filament specifically designed for metal printing. Many 3D printer manufacturers already sell filaments that contain metal dust. They are what make materials that imitate metal when adding finishing touches to a plastic 3D printed object. However, these are not the filaments of which will be tackled here. Instead, we are talking about a filament that is printed in 3D and used to make 100% metal parts. There are few companies in the world making 3D metal printing filaments. BASF from Germany is a good example.

The filament is made from a huge amount of metallic dust. The dust is fed into a conventional FDM 3D printer and then used in a metal printing printer. The metallic dust comes from 316L stainless steel. It is stronger and more expensive than regular stainless steel as well as being highly resistant to corrosion.

However, the filament only contains 90% metal with the rest being a thermoplastic which remains in the dust in thread form as a result of 3D printing.

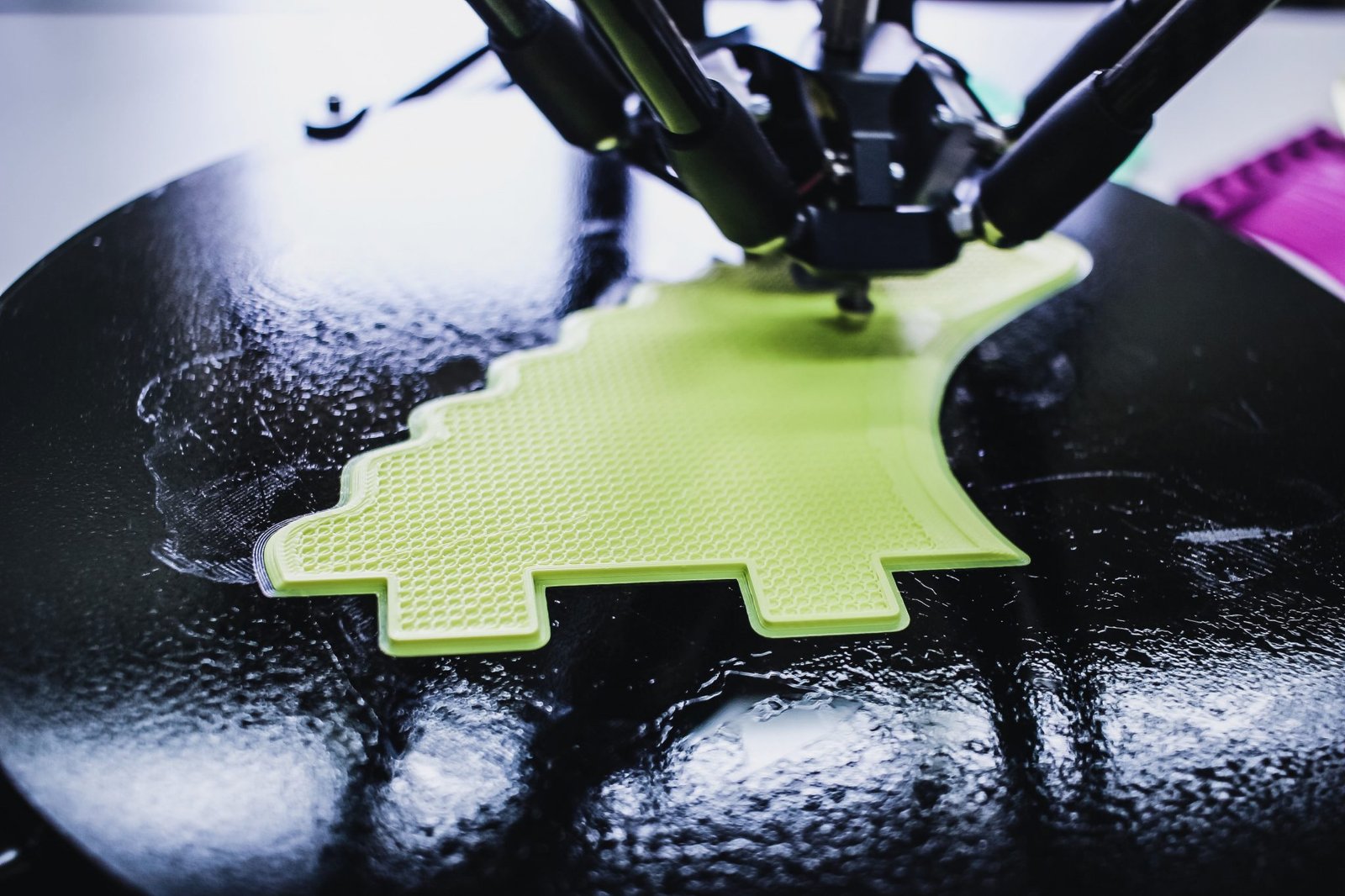

Methods for 3D Metal Printing

Once you have a filament, there are three ways you can use it to print the metal. They are dependent on the type of printer, hence, it is vital to read 3D printer reviews. They will tell you which process is best.

Metal Binder Jetting

Metal binder jetting is a process that starts just like any other 3D printing process. The only difference is that instead of plastic being extruded, metal is used instead. The metal powder is deposited in thin layers and held together by a glue-like binding substance. They fuse together and build upwards to create the final product. The process repeats until all layers are completed from the bottom to the top. It is a process that takes hours.

Powder Bed Fusion

Powder bed fusion appears to be the same as metal binder jetting. The main difference is that instead of using a binder to fuse the metal layers, powder bed fusion uses a high-temperature laser or electron beam.

By increasing the temperature of the metal powder in areas where it is being fused, it creates a continuous layer. The layers eventually become a solid object. There are several techniques you can use to perform powder bed fusion.

Direct Energy Deposition

Direct energy deposition uses either metal powder or metal wire for printing. It involves a nozzle moving in many directions that deposits metal powder or wire layer by layer according to the object being created. Once it is deposited, a laser or electron beam is used to melt and fuse the layers together. The process continues layer by layer until the object is complete. Direct energy deposition is typically used to repair and maintain existing objects. However, it has been adapted to make objects from nothing.

Post Processing

Though you might have a 3D metal printer at home, the post-processing of the object might have to be done by an external party. It is usually an external company with advanced 3D technology.

The post-processing of a 3D printed metal object involves several steps. The first step is washing, also known as debinding. The 3D printed metal object is washed by immersing it in an atmosphere of vaporized nitric acid.

It is then heated to separate the plastic from the metal in the object. The result is only the metal remains, leaving a metal often called the brown part. The brown part is then reheated in an oven to fuse its layers without melting it in a process called sintering. Once finished, you have a complete metallic 3D printed object.

There are several ways to perform 3D metal printing at home. However, post-processing cannot be done at home unless you are fine with a plastic and metal hybrid. If you can get a good filament, you can make any metallic 3D object you want.